We are starting mass

production of the new KONA

Electric

5 minutes of reading | 15.8.2023

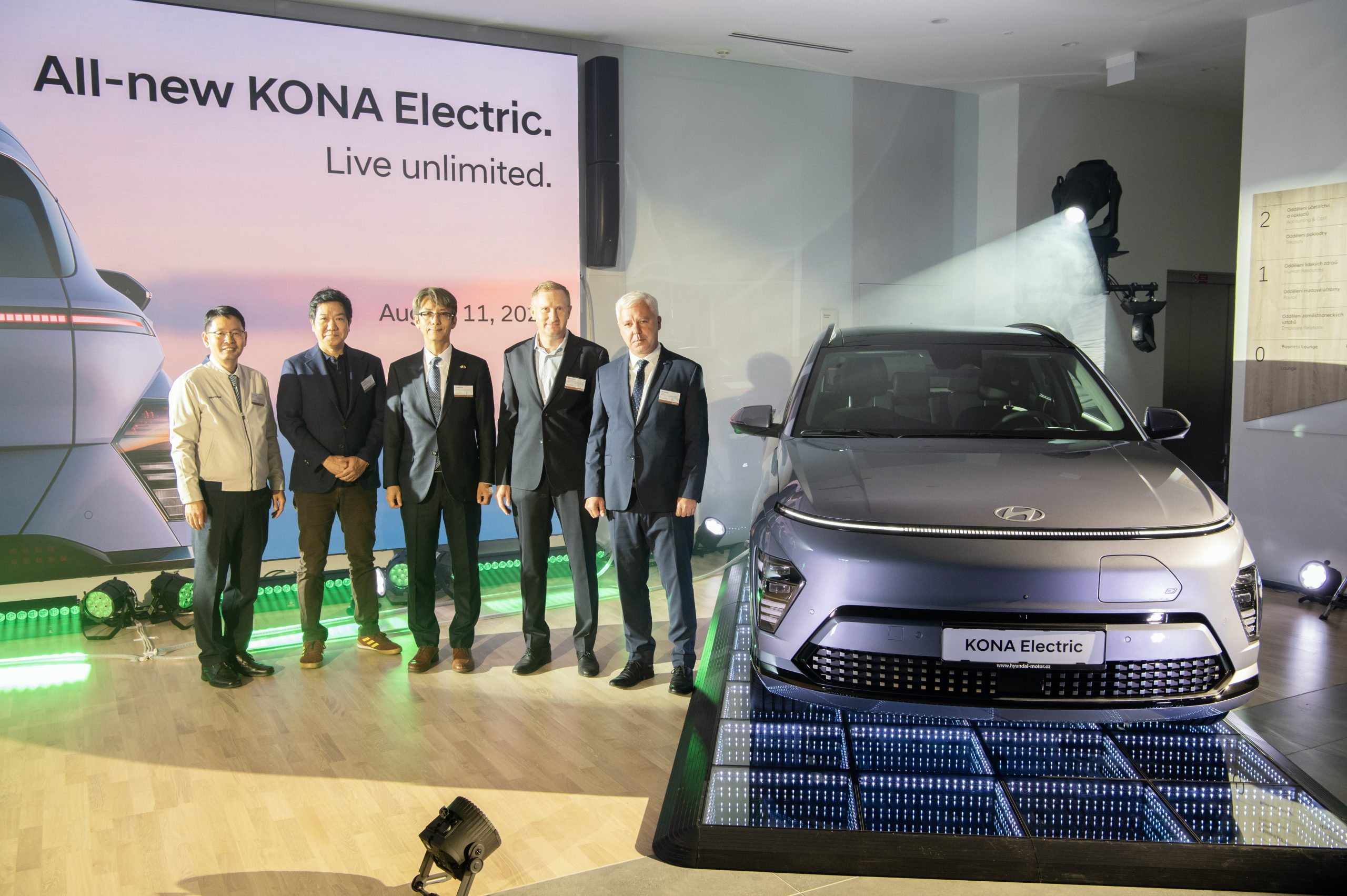

We have started series production of the new generation Hyundai KONA Electric, which follows the successful first generation electric car.

“We have been producing the all-electric Kona in Nošovice since March 2020, making it the first new-generation electric car to be produced in the Czech Republic. This was a groundbreaking event for our production plant. We have embarked on a successful journey towards an electrified future and clean mobility and applied a number of new technologies. Hyundai has a strong position in the electric vehicle segment, and I have no doubt that the new KONA Electric will be a successful successor to the previous generation thanks to its qualities,” noted HMMC President Changki Lee.

The new KONA Electric offers an attractive design, larger dimensions, more space in the interior and boot, as well as new technologies and useful equipment features that contribute to a safe, networked and comfortable driving experience. A new generation of the information system, wireless updates of the map data and vehicle control software, a panoramic display area consisting of two 12.3″ displays and a digital key system all help to take connectivity to the next level. An interesting feature is the V2L (Vehicle-to-Load) function, which allows the new KONA Electric to power or charge any electrical device thanks to the two-way on-board charger. Practicality is enhanced by the positioning of electrical sockets in the interior and exterior.

The new KONA has excellent driving characteristics and is equipped with the latest Hyundai Smart Sense safety and assistance systems and advanced parking assistance systems (detailed product information on the new KONA Electric is available, among others, on the website of the Czech Hyundai dealership).

We will continue to produce two differently powerful versions of the KONA Electric with different battery capacities, but both versions will offer more power and range than before. The KONA Electric with a 160 kW electric motor is equipped with a 65.4 kWh battery pack and has the longest range in its class at 514 km (WLTP). The base version will offer a 48.4 kWh battery pack and a 114.6 kW electric motor. The battery cells are manufactured at LG Energy Solution’s plant in Wroclaw, Poland. The batteries are then assembled into their final form in the Nošovice industrial zone, at Mobis’ facility in the former Transmission Shop No. 2, where manual transmissions were manufactured until the end of 2021.

Cooperation of Nošovice engineers on development

The launch of the new generation of the electric car required a number of modifications and innovations. For example, calibration of the front radars and the head-up display on the newly installed fully robotic workstation are now required in production. It was necessary to modify all the robots, of which there are more than five hundred, as well as the manipulators.

Experts from our plant also had a significant say in the development of the new model. Whereas previously the Nošovice engineers cooperated with the development centre from the moment the local developers prepared the prototype, now they are involved in the development already at the time of preparing the drawings. “So we are already influencing the drawings, not just the prototypes. This gives us the opportunity to influence the character and parameters of the car, but also to take into account the specifics of our plant,” said Martin Klíčník, head of the production subdivision. This wider and closer involvement of Nošovice engineers in development applies not only to the new generation KONA Electric, but also to all other upcoming model innovations. It was thus necessary to strengthen the teams of local engineers.

“We are gradually taking over responsibility for the complete preparation of our production lines for the new models. We are testing pilot cars on European roads and, in cooperation with the Hyundai development centre in Rüsselsheim, Germany, we are coming up with ideas and suggestions to improve them from the point of view of the European customer,” adds the head of the production subdivision.

From Nošovice not only to Europe

In the three and a quarter years since production began, nearly 105,000 first-generation KONA Electrics have been produced. The electric vehicle accounted for approximately one tenth of the total production of the Nošovice plant. More than four-fifths of the production was destined for four European markets that have a major share in the rapid development of electric mobility on the old continent – namely Germany, France, Norway and the Netherlands. As before, the next-generation KONA Electric will also be produced in South Korea, primarily for that market and other overseas destinations.

We expect the KONA Electric’s share of the factory’s total production to reach 15% later this year, thanks in part to the fact that the electric vehicle will be delivered to an additional 20 countries compared to the current figure (22 exclusively European countries this year). By the end of 2023, 21,000 cars of the new generation KONA Electric are to be produced, with 50,000 next year. The KONA Electric will now be produced here in a right-hand drive version for the UK, Ireland and Cyprus. New destinations for the electric car from Nošovice will also include Turkey, Israel, as well as the exotic Reunion and Guadalupe.

Towards clean mobility

European and global demand for electric vehicles is rising faster than market forecasts. The growing interest in electrified vehicles is also evident in our plant’s production. The share of hybrids, plug-in hybrids and electric vehicles in production is over 40% this year and is thus growing steadily. No such vehicles were produced in Nošovice as recently as 2019.

The Hyundai brand will only offer zero-emission vehicles in the European region from 2035. In line with the transition to clean mobility, the portfolio of pure electric models produced at HMMC will be expanded in the coming years. By adapting to the rapid development of electric mobility, the Nošovice plant is best placed to continue to play an important role for the entire Hyundai Group in the future.

The successful achievement of CO2 emission targets and the increase in the share of emission-free vehicles in European sales is not a matter of chance, but the result of the targeted implementation of Hyundai’s strategy towards electrification and transformation into a provider of smart mobility solutions. Hyundai will continue to lead the electrification of the automotive industry. Compared to other manufacturers, Hyundai offers the widest range of powertrains – from internal combustion engines to partial hybrid, hybrid and externally chargeable hybrid systems to electric vehicles powered by batteries or even hydrogen fuel cells. In the case of the new generation KONA, for example, customers can choose between electric drive, hybrid drive and internal combustion engine variants.